Lean tools list

Home » Project Example » Lean tools listLean tools list

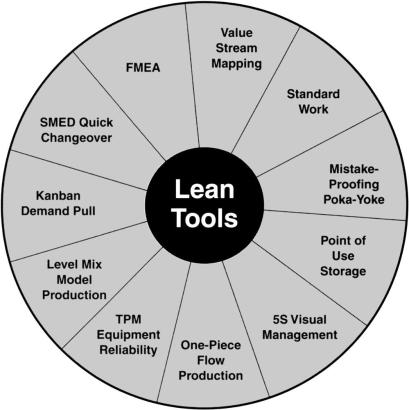

Lean Tools List. Kaizen is the Japanese word for good change and represents the idea of continuous improvement. The purpose of 5S is to reduce wasteful time and motion at a micro level. Grouped components and manufacturing cells. It is an organized approach to housekeeping that ensures tools parts and other objects are in known optimum locations.

There S A Tool For That 100 Lean Tools In One Click Impruver Com From impruver.com

There S A Tool For That 100 Lean Tools In One Click Impruver Com From impruver.com

Poka-Yoke is one of the most important Lean techniques. The names of these Lean tools are self-explanatory. Its objective is to reduce tool changeover times in production as much as possible. 5S gets its name from five Japanese words that act as guiding principles for the system. It is a Lean method developed by Shigeo Shingo at Toyota. The Ultimate List Tel.

What is Bottleneck Analysis.

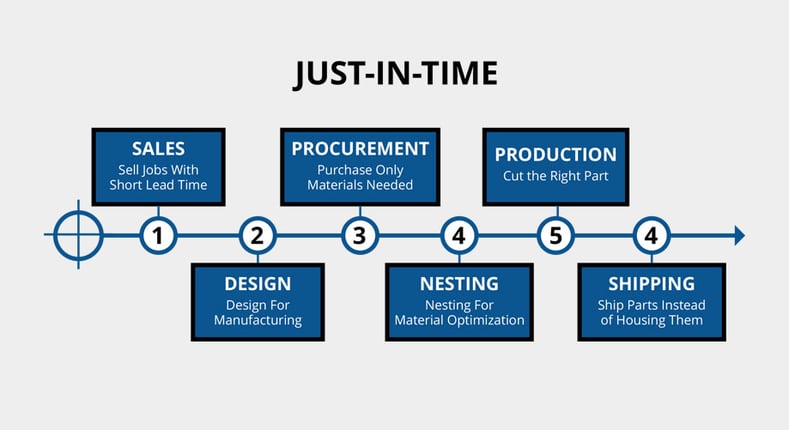

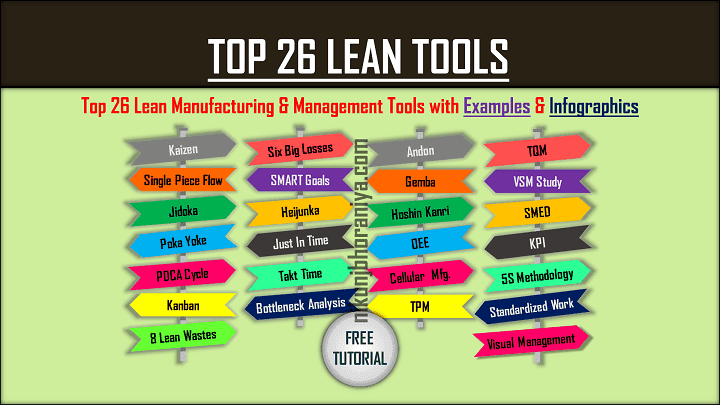

Its objective is to reduce tool changeover times in production as much as possible. The list of top lean tools are. These are just a few of the lean tools. A quick list of the main Lean Manufacturing Tools Of course there are many others but these are the primary tools that can resolve most any manufacturing issues most all of the time. The method consists of five steps. Nothing can slow or stop this flow faster than the loss or misplacement of tools.

Source: leanmanufacturingtools.org

Source: leanmanufacturingtools.org

The Bottleneck Analysis is a potent Lean tool if your company is suffering due to a lack of an organized structure. What is Continuous Flow. The Ultimate List Tel. 35 Lean Manufacturing Tools. The Bottleneck Analysis is a potent Lean tool if your company is suffering due to a lack of an organized structure.

Source: nikunjbhoraniya.com

Source: nikunjbhoraniya.com

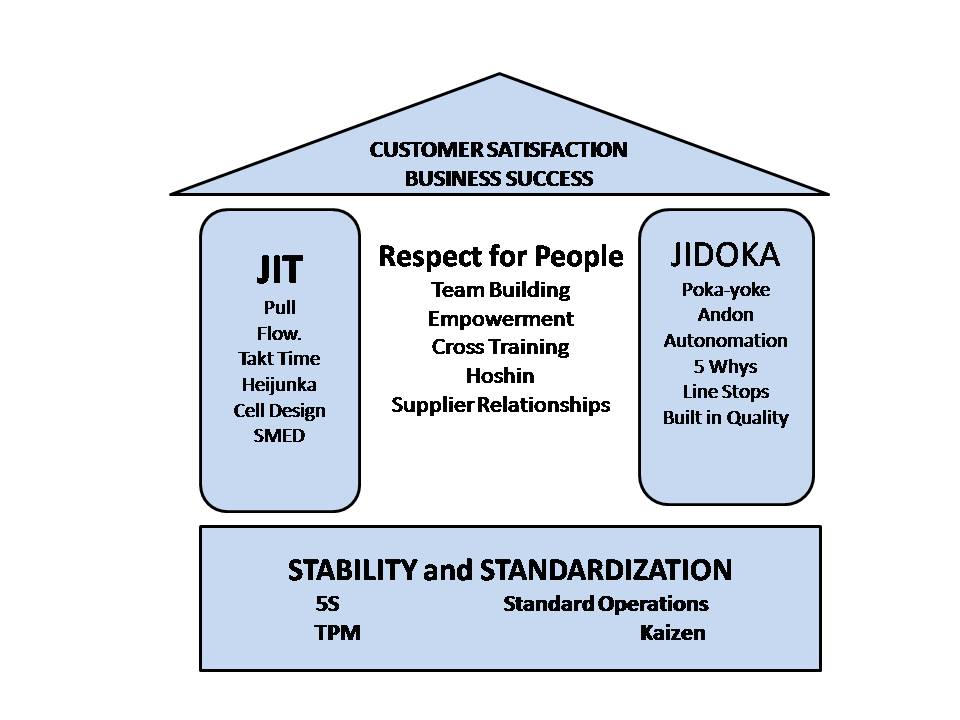

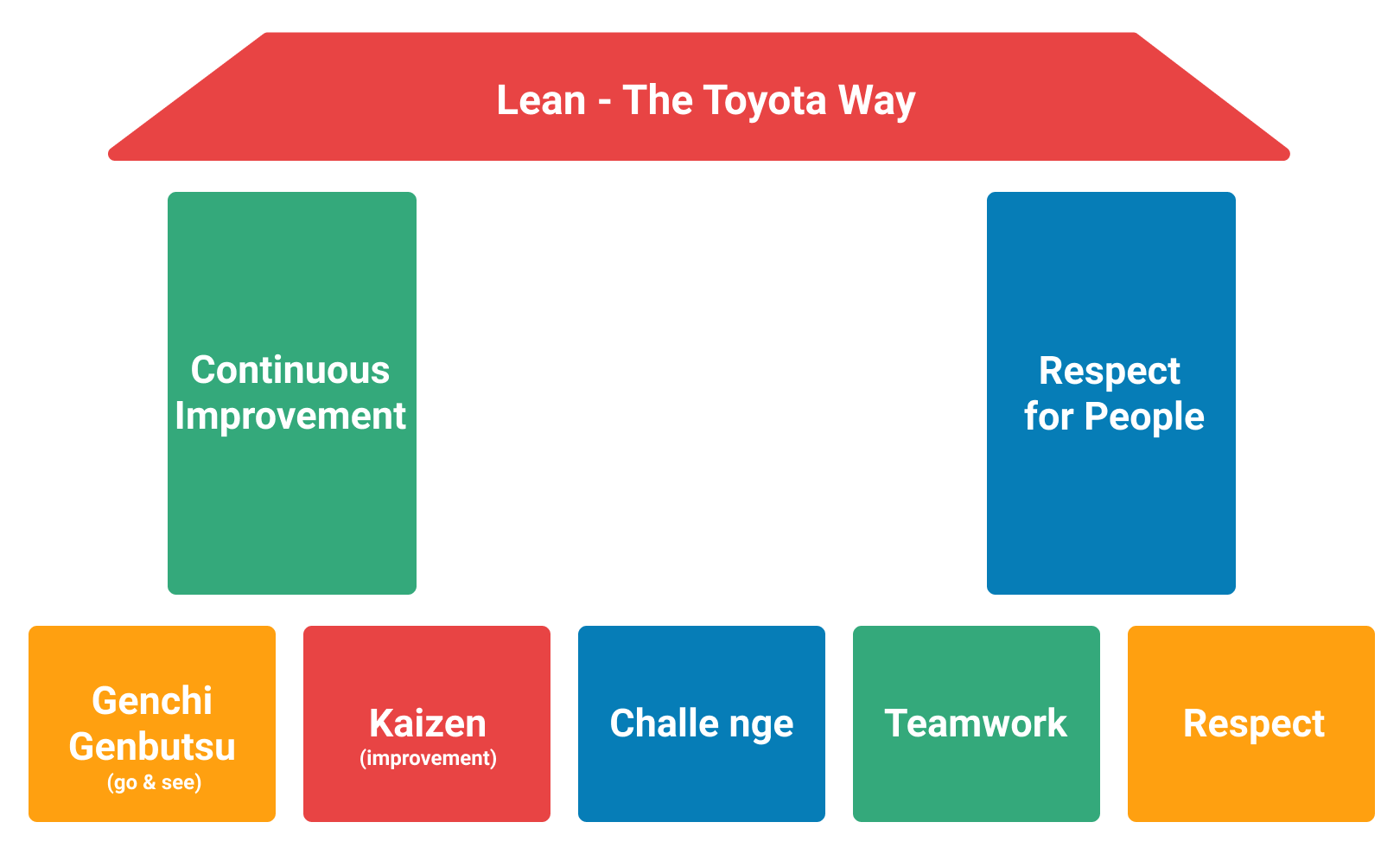

Lean methodology also has an expansive legacy outside the US with companies such as Toyota making considerable breakthroughs in the application of Lean Tools throughout the 1930s. However Kaizen 5S Kanban Value Stream Mapping and Focus PDCA are among the most useful lean tools. In this article well explore what Lean tools are and discuss the applications for seven common ones that youll encounter in Lean. The Ultimate List Tel. There are a multitude of Lean Six Sigma Tools but not all of them are used often or prove to be as valuable as others.

Source: impruver.com

Source: impruver.com

What is Continuous Flow. Jidoka Autonomation Jidoka is another Lean manufacturing tool of Japanese origin. Overall Equipment Effectiveness OEE Plan Do Check Act PDCA Error Proofing. What is Continuous Flow. Of all the Lean Techniques 5S is the one that is focused on organizing.

Source: leanmanufacturingtools.org

Source: leanmanufacturingtools.org

The Gemba is one of three important Lean manufacturing tools that can help leaders approach their role with greater humility as they sharpen their analytical skills. These are just a few of the lean tools. It uses a six-dimensional model that includes leadership support systems value stream continuous improvement lean techniques and standard work. Lean methodology also has an expansive legacy outside the US with companies such as Toyota making considerable breakthroughs in the application of Lean Tools throughout the 1930s. This template is a Microsoft Excel document which can be used to suit your specific needs.

Source: quality-assurance-solutions.com

Source: quality-assurance-solutions.com

It is an organized approach to housekeeping that ensures tools parts and other objects are in known optimum locations. Poka-Yoke is one of the most important Lean techniques. You may conduct lean audits on a periodic basis for example annually or whenever it is needed. The purpose of 5S is to reduce wasteful time and motion at a micro level. Lean Tools are also used for identifying and eliminating waste from the system or process.

Source: resources.hartfordtechnologies.com

Source: resources.hartfordtechnologies.com

It is a Lean method developed by Shigeo Shingo at Toyota. A quick list of the main Lean Manufacturing Tools Of course there are many others but these are the primary tools that can resolve most any manufacturing issues most all of the time. It is an organized approach to housekeeping that ensures tools parts and other objects are in known optimum locations. These are just a few of the lean tools. The Ultimate List Tel.

Source: process.st

Source: process.st

The list of top lean tools are. It uses a six-dimensional model that includes leadership support systems value stream continuous improvement lean techniques and standard work. Visual feedback system for the plant floor that indicates production status alerts when. The Bottleneck Analysis is a potent Lean tool if your company is suffering due to a lack of an organized structure. Process Walk Interview Sheet.

Source: kanbanize.com

Source: kanbanize.com

Also known as the KJ method Affinity Diagram is an analytical tool where different ideas from different people working in that industry relating to a specific problem are combined and then classified according to their relationship. Cellular manufacturing is a lean manufacturing approach for process improvement. A quick list of the main Lean Manufacturing Tools Of course there are many others but these are the primary tools that can resolve most any manufacturing issues most all of the time. Poka-Yoke is one of the most important Lean techniques. Visual feedback system for the plant floor that indicates production status alerts when.

Source: flexqube.com

Source: flexqube.com

Kaizen is the Japanese word for good change and represents the idea of continuous improvement. The names of these Lean tools are self-explanatory. 5 Kaizen aka Continuous Improvement What is kaizen. 5S is one of them. Identify the operations performed.

Source: nikunjbhoraniya.com

Source: nikunjbhoraniya.com

Its objective is to reduce tool changeover times in production as much as possible. Some lean tools may be more appropriate for one business than another. WHAT IT IS The 5S System offers a systematic approach for rooting out inefficiencies improving organization and implementing standardized practices throughout a facility. 5S is one of them. Lean Techniques 3 5S.

Source: researchgate.net

Source: researchgate.net

Six Sigma Tools for DEFINE Phase. You may conduct lean audits on a periodic basis for example annually or whenever it is needed. The names of these Lean tools are self-explanatory. Thus all tools used at a workstation should have their own holder. Cellular manufacturing is a lean manufacturing approach for process improvement.

Source: researchgate.net

Source: researchgate.net

35 Lean Manufacturing Tools. It is a Lean method developed by Shigeo Shingo at Toyota. 35 Lean Manufacturing Tools. Process Walk Interview Sheet. In this article well explore what Lean tools are and discuss the applications for seven common ones that youll encounter in Lean.

Source: leanmanufacturingsecrets.com

Source: leanmanufacturingsecrets.com

It uses a six-dimensional model that includes leadership support systems value stream continuous improvement lean techniques and standard work. Nothing can slow or stop this flow faster than the loss or misplacement of tools. Lean methodology also has an expansive legacy outside the US with companies such as Toyota making considerable breakthroughs in the application of Lean Tools throughout the 1930s. Lean Tools are also used for identifying and eliminating waste from the system or process. 35 Lean Manufacturing Tools.

Source: techqualitypedia.com

Source: techqualitypedia.com

A quick list of the main Lean Manufacturing Tools Of course there are many others but these are the primary tools that can resolve most any manufacturing issues most all of the time. Cellular manufacturing What is it cellular manufacturing. Some lean tools may be more appropriate for one business than another. Clicking on the View All link below will give you additional information on each of these key tools. Its a primary tool to preserve the output of processes and make problems visible.

Source: planview.com

Source: planview.com

Process Walk Interview Sheet. 5S gets its name from five Japanese words that act as guiding principles for the system. However Kaizen 5S Kanban Value Stream Mapping and Focus PDCA are among the most useful lean tools. Principles Tools and Methods 1 6 Bosch Rexroth Corporation A smooth uninterrupted flow of complet-ed workpieces is the desired result of a properly designed lean workcell. The Gemba is one of three important Lean manufacturing tools that can help leaders approach their role with greater humility as they sharpen their analytical skills.

If you find this site adventageous, please support us by sharing this posts to your preference social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title lean tools list by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.